| Availability: | |

|---|---|

| Quantity: | |

LD10018BUR

LITEKEY

8531200000

1.0 inch Red Alpha-numeric LED Display(LD10018BUR)

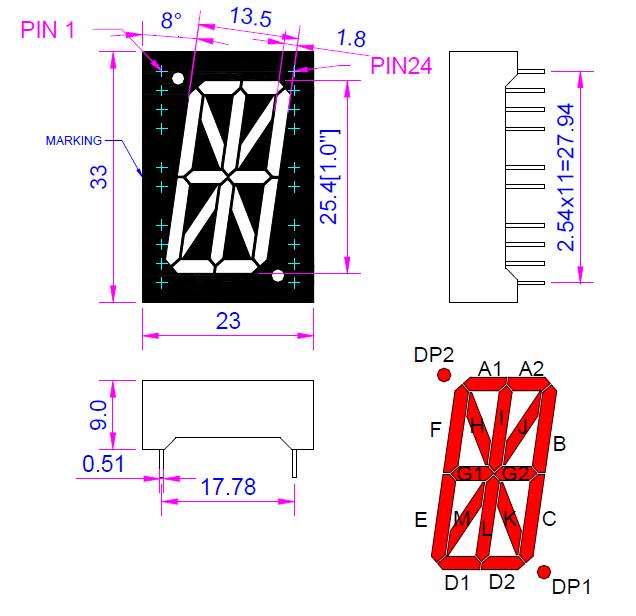

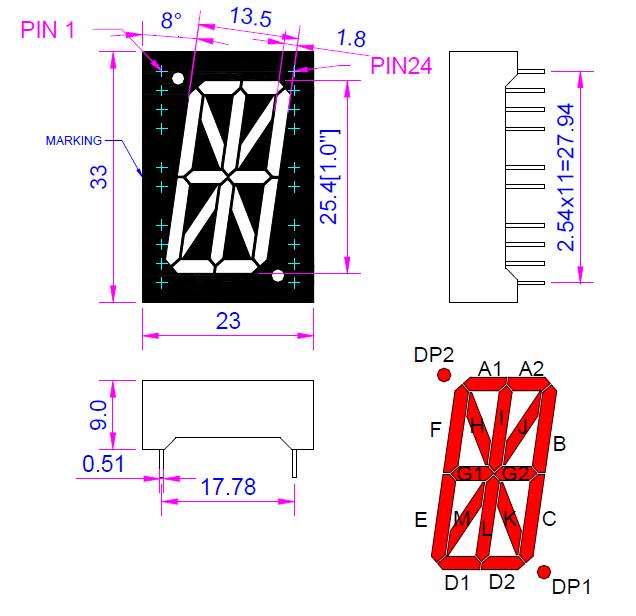

1. Outer Dumension and Internal Circuit Diagram

Notes:

All dimensions are in millimeters (inches) tolerance are 0.25mm(0.010) unless otherwise noted.

Contact us for internal circuit!

2. Characters

CHARACTERS |

| Chip Material: AlGaInP Ultra Bright Red LED Chip |

3.Absolute Maximum Ratings(Ta=25℃)

PARAMETER | SYMBOL | MAXIMUM RATING | UNIT |

Power Dissipation | PD | 78 | mW |

Peak Forward Current (1/10 Duty Cycle, 0.1 ms Pulse Width) | IPEAK | 90 | mA |

DC Forward Current | IF | 30 | mA |

Reverse Voltage | VR | 5 | V |

Electrostatic discharge | ESD | 1000 | V |

Operating Temperature Range | Topr / Tstg | -40°C to +85°C | |

Storage Temperature Range | Topr / Tstg | -40°C to +100°C | |

4. Electrical Characteristics & Absolute Maximum Ratings

PARAMETER | SYMBOL | MIN | TYP | MAX | UNIT | TEST CONDITION (Per Chip) |

Forward Voltage | VF | - | 2.0 | 2.6 | V | IF =20mA |

Luminous Intensity | IV | 30 | 45 | - | mcd | IF =20mA |

Peak Emission Wavelength | λp | - | 640 | - | nm | IF =20mA |

Dominant Emission Wavelength | λd | - | 630 | - | nm | IF =20mA |

Spectral Line Half-Width | Δλ | - | 20 | - | nm | IF =20mA |

Reverse Current | IR | - | - | 10 | uA | VR = 5V |

Contact us for more details.

Our QC System:

Factory Overview and production process

Our Services/Why choose LITEKEY

1. Professional service: replied within 24 hours(at workdays).

2. Various ready moldings of lamp led are available: no need to afford extra fee for moldings.

3. We also can provide customized products, design according to your demand.

4. Reliable and stable quality: 100% testing for each piece. Automatic testing and bin code selection machine.

5. Experience: produce LED components for more than 14 years.

6. Advanced Equipment: ASM automatic production machines(biggest brand in LED automatic machines)

7. Concentration: We focus on LED research and development, production and sales.

1.0 inch Red Alpha-numeric LED Display(LD10018BUR)

1. Outer Dumension and Internal Circuit Diagram

Notes:

All dimensions are in millimeters (inches) tolerance are 0.25mm(0.010) unless otherwise noted.

Contact us for internal circuit!

2. Characters

CHARACTERS |

| Chip Material: AlGaInP Ultra Bright Red LED Chip |

3.Absolute Maximum Ratings(Ta=25℃)

PARAMETER | SYMBOL | MAXIMUM RATING | UNIT |

Power Dissipation | PD | 78 | mW |

Peak Forward Current (1/10 Duty Cycle, 0.1 ms Pulse Width) | IPEAK | 90 | mA |

DC Forward Current | IF | 30 | mA |

Reverse Voltage | VR | 5 | V |

Electrostatic discharge | ESD | 1000 | V |

Operating Temperature Range | Topr / Tstg | -40°C to +85°C | |

Storage Temperature Range | Topr / Tstg | -40°C to +100°C | |

4. Electrical Characteristics & Absolute Maximum Ratings

PARAMETER | SYMBOL | MIN | TYP | MAX | UNIT | TEST CONDITION (Per Chip) |

Forward Voltage | VF | - | 2.0 | 2.6 | V | IF =20mA |

Luminous Intensity | IV | 30 | 45 | - | mcd | IF =20mA |

Peak Emission Wavelength | λp | - | 640 | - | nm | IF =20mA |

Dominant Emission Wavelength | λd | - | 630 | - | nm | IF =20mA |

Spectral Line Half-Width | Δλ | - | 20 | - | nm | IF =20mA |

Reverse Current | IR | - | - | 10 | uA | VR = 5V |

Contact us for more details.

Our QC System:

Factory Overview and production process

Our Services/Why choose LITEKEY

1. Professional service: replied within 24 hours(at workdays).

2. Various ready moldings of lamp led are available: no need to afford extra fee for moldings.

3. We also can provide customized products, design according to your demand.

4. Reliable and stable quality: 100% testing for each piece. Automatic testing and bin code selection machine.

5. Experience: produce LED components for more than 14 years.

6. Advanced Equipment: ASM automatic production machines(biggest brand in LED automatic machines)

7. Concentration: We focus on LED research and development, production and sales.

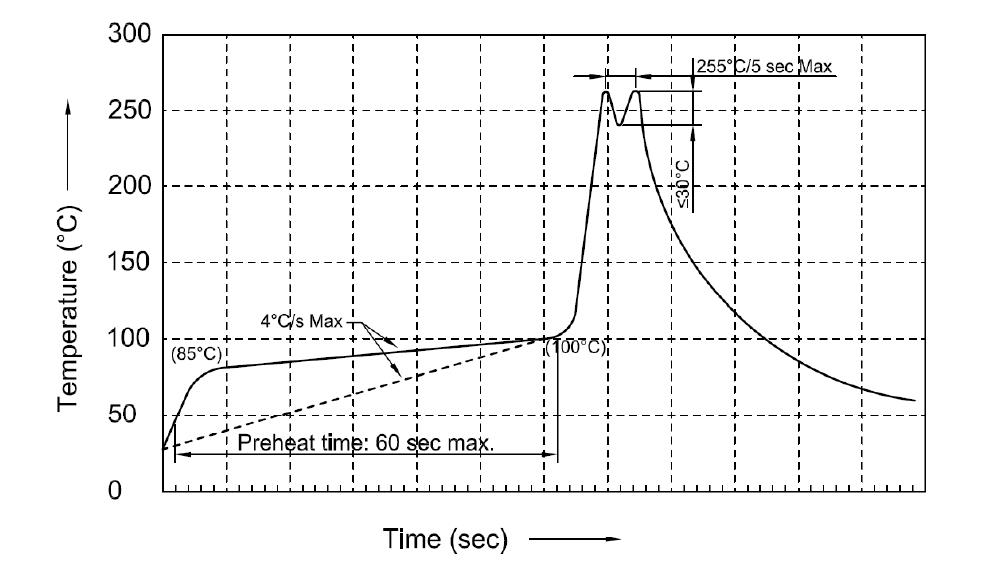

Recommended Wave Soldering Profiles

Notes:

1.Recommend pre-heat temperature of 105℃ or less (as measured with a thermocouple

attached to the LED pins) prior to immersion in the solder wave with a maximum solder bath

temperature of 260℃.

2.Peak wave soldering temperature between 245-255℃ for 3 sec (5 sec max).

3.Do not apply stress to the epoxy resin while the temperature is above 85℃.

4.Fixtures should not apply stress on the component when mounting and soldering process.

5.More than one wave soldering is not allowed.

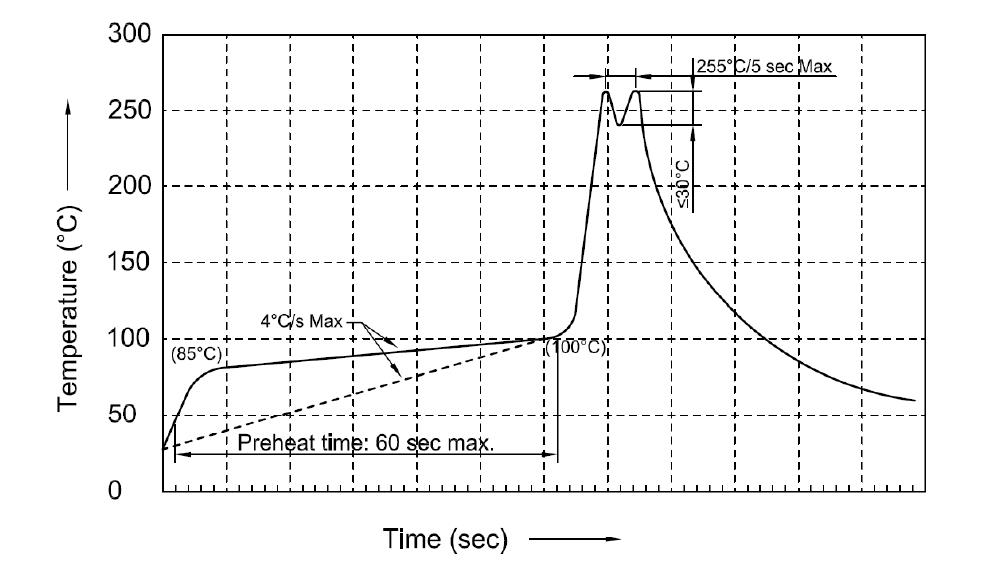

Recommended Wave Soldering Profiles

Notes:

1.Recommend pre-heat temperature of 105℃ or less (as measured with a thermocouple

attached to the LED pins) prior to immersion in the solder wave with a maximum solder bath

temperature of 260℃.

2.Peak wave soldering temperature between 245-255℃ for 3 sec (5 sec max).

3.Do not apply stress to the epoxy resin while the temperature is above 85℃.

4.Fixtures should not apply stress on the component when mounting and soldering process.

5.More than one wave soldering is not allowed.