LLS5050RGB3-R10

LITEKEY

8541401000

5050 RGB Surface Mount LED (LLS5050RGB3-R10)

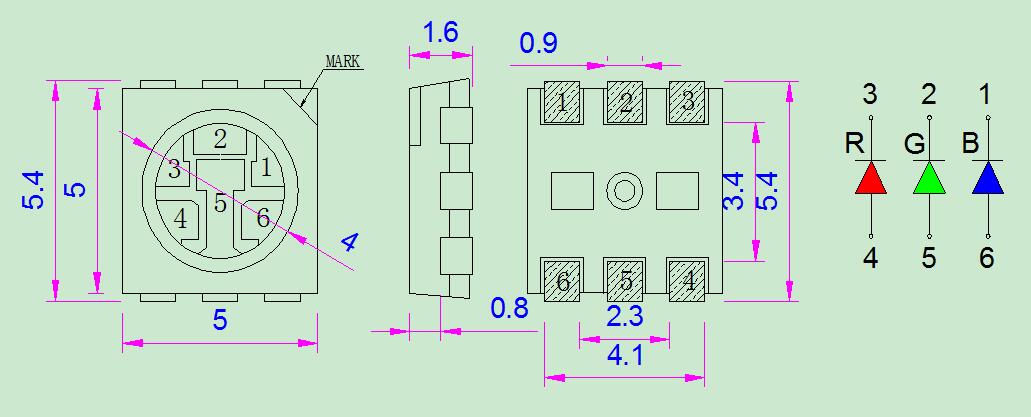

·Package Dimensions

NOTES:

1.All dimensions are in millimeter[unit];

2.Tolerance is±0.1mm(0.004”) unless other specified;

3.Specifications are subject to change without notice.

·

·

Features:

5.0mm×5.0mm SMT LED,1.60mm thickness

PLCC-6 package

White package

Suitable for all SMT assembly and solder process

Available on 8mm tape and on 178mm reel

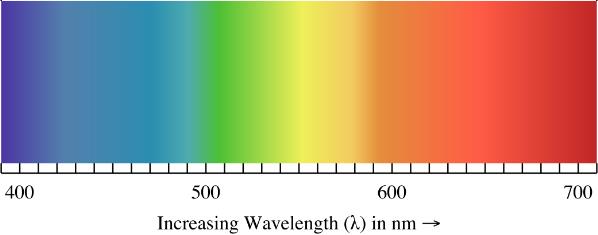

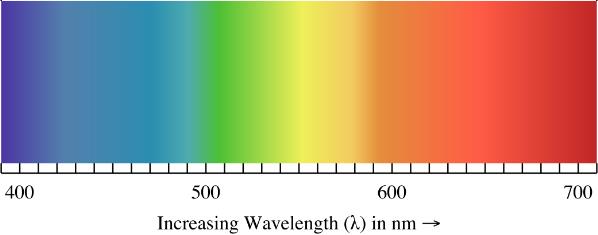

Dominant Wavelength Red (619 - 624nm) Green (520 - 535nm) Blue (460 - 475nm)

Moisture Sensitivity Level: 5a

Lead-Free

RoHS Compliant

PLCC6 3 in 1 SMD LED

PRODUCT DESCRIPTION

These SMD LEDs are packaged in an industry standard PLCC6 package. These high performance RGB SMT LEDs are designed to work in a wide range of applications. A wide viewing angle and high brightness make these LEDs suitable for signage applications.

APPLICATIONS

Architecture Lighting

Decorative Lighting

Amusement

Part No. | Emitted Color | Len’s Color | Chip Material | ||||

LLS5050RGB3-R10 | Red | Green | Blue | Water clear | AlGaInP | InGaN | InGaN |

·Absolute Maximum Ratings(Ta=25℃)

Item | Symbol | Maximum | Unit | |

Power Dissipation | PD | R | 78 | mW |

G | 90 | |||

B | 90 | |||

Forward Current | IF | R | 30 | mA |

G/B | 25 | |||

Peak Forward Current(1/10 Duty Cycle 0.1ms Pulse Width) | IFP | R | 90 | mA |

G/B | 100 | |||

Reverse Voltage | VR | 5 | V | |

Electrostatic discharge | ESD | 1000 | V | |

Operating Temperature Range | Topr / Tstg | -40 to+85 | ℃ | |

Storage Temperature Range | Topr / Tstg | -40 to+85 | ℃ | |

·Electrical/Optical Characteristics(Ta=25℃)

Item | Symbol | Condition | Min. | Typ. | Max | Unit | |

Forward Voltage | VF | R | IF=20mA | -- | 2.0 | 2.6 | V |

G/B | -- | 3.0 | 3.6 | ||||

Luminous Intensity | IV | R | IF=20mA | 200 | 400 | -- | mcd |

G | 500 | 1000 | -- | ||||

B | 180 | 300 | -- | ||||

Wavelength | d | R | IF=20mA | - | 625 | - | nm |

G | - | 520 | - | ||||

B | - | 470 | - | ||||

Viewing Angle | 2θ1/2 | IF=20mA | --- | 120 | --- | deg | |

Reverse Current | IR | VR =5V | --- | -- | 10 | uA | |

NOTES:

1. Tolerance is ±0.25mm unless other specified;

2. Luminous intensity testing tolerance is ±10%;

3. Dominant Emission Wavelength testing tolerance is ±1nm;

4. Specifications are subject to change without notice.

·Typical Electro-Optical Characteristics Curves

·Reliability Test Items And Conditions

NO. | Item | Test Condition | Test Hr/cycle/time | Sample Qty | Ac/Re |

1 | Reflow | TEMP:260±5℃; (3-7 sec) | 6 min | 22pcs | 0/1 |

2 | High Temperature /Humidity Storage | TEMP: 85℃/ R.H.:85% | 1000hrs | 22pcs | 0/1 |

3 | Low Temperature Storage | TEMP: -40℃ | 1000hrs | 22pcs | 0/1 |

4 | DC Operating Life | IF=20mA | 1000hrs | 22pcs | 0/1 |

5050 RGB Surface Mount LED (LLS5050RGB3-R10)

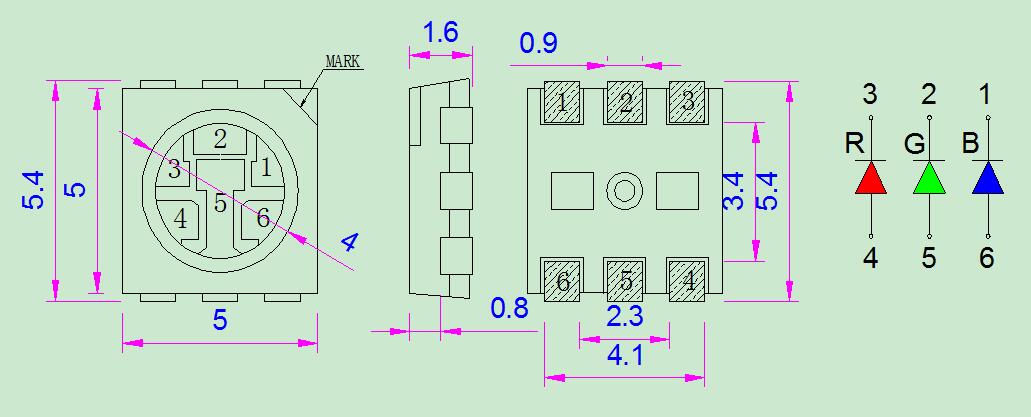

·Package Dimensions

NOTES:

1.All dimensions are in millimeter[unit];

2.Tolerance is±0.1mm(0.004”) unless other specified;

3.Specifications are subject to change without notice.

·

·

Features:

5.0mm×5.0mm SMT LED,1.60mm thickness

PLCC-6 package

White package

Suitable for all SMT assembly and solder process

Available on 8mm tape and on 178mm reel

Dominant Wavelength Red (619 - 624nm) Green (520 - 535nm) Blue (460 - 475nm)

Moisture Sensitivity Level: 5a

Lead-Free

RoHS Compliant

PLCC6 3 in 1 SMD LED

PRODUCT DESCRIPTION

These SMD LEDs are packaged in an industry standard PLCC6 package. These high performance RGB SMT LEDs are designed to work in a wide range of applications. A wide viewing angle and high brightness make these LEDs suitable for signage applications.

APPLICATIONS

Architecture Lighting

Decorative Lighting

Amusement

Part No. | Emitted Color | Len’s Color | Chip Material | ||||

LLS5050RGB3-R10 | Red | Green | Blue | Water clear | AlGaInP | InGaN | InGaN |

·Absolute Maximum Ratings(Ta=25℃)

Item | Symbol | Maximum | Unit | |

Power Dissipation | PD | R | 78 | mW |

G | 90 | |||

B | 90 | |||

Forward Current | IF | R | 30 | mA |

G/B | 25 | |||

Peak Forward Current(1/10 Duty Cycle 0.1ms Pulse Width) | IFP | R | 90 | mA |

G/B | 100 | |||

Reverse Voltage | VR | 5 | V | |

Electrostatic discharge | ESD | 1000 | V | |

Operating Temperature Range | Topr / Tstg | -40 to+85 | ℃ | |

Storage Temperature Range | Topr / Tstg | -40 to+85 | ℃ | |

·Electrical/Optical Characteristics(Ta=25℃)

Item | Symbol | Condition | Min. | Typ. | Max | Unit | |

Forward Voltage | VF | R | IF=20mA | -- | 2.0 | 2.6 | V |

G/B | -- | 3.0 | 3.6 | ||||

Luminous Intensity | IV | R | IF=20mA | 200 | 400 | -- | mcd |

G | 500 | 1000 | -- | ||||

B | 180 | 300 | -- | ||||

Wavelength | d | R | IF=20mA | - | 625 | - | nm |

G | - | 520 | - | ||||

B | - | 470 | - | ||||

Viewing Angle | 2θ1/2 | IF=20mA | --- | 120 | --- | deg | |

Reverse Current | IR | VR =5V | --- | -- | 10 | uA | |

NOTES:

1. Tolerance is ±0.25mm unless other specified;

2. Luminous intensity testing tolerance is ±10%;

3. Dominant Emission Wavelength testing tolerance is ±1nm;

4. Specifications are subject to change without notice.

·Typical Electro-Optical Characteristics Curves

·Reliability Test Items And Conditions

NO. | Item | Test Condition | Test Hr/cycle/time | Sample Qty | Ac/Re |

1 | Reflow | TEMP:260±5℃; (3-7 sec) | 6 min | 22pcs | 0/1 |

2 | High Temperature /Humidity Storage | TEMP: 85℃/ R.H.:85% | 1000hrs | 22pcs | 0/1 |

3 | Low Temperature Storage | TEMP: -40℃ | 1000hrs | 22pcs | 0/1 |

4 | DC Operating Life | IF=20mA | 1000hrs | 22pcs | 0/1 |

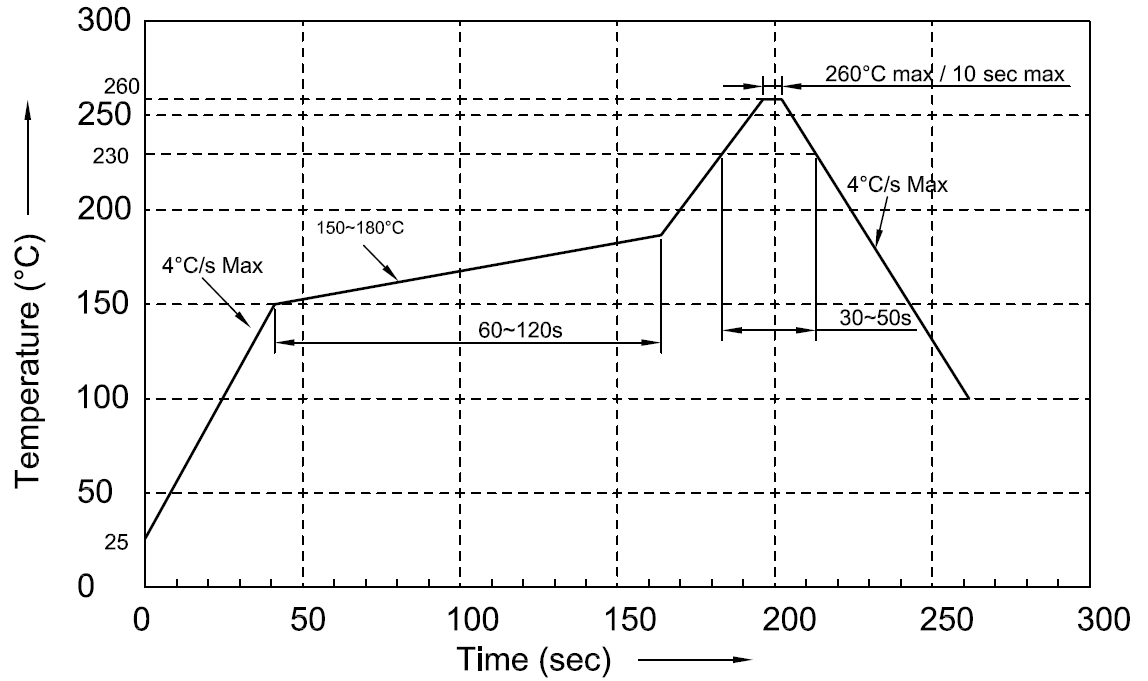

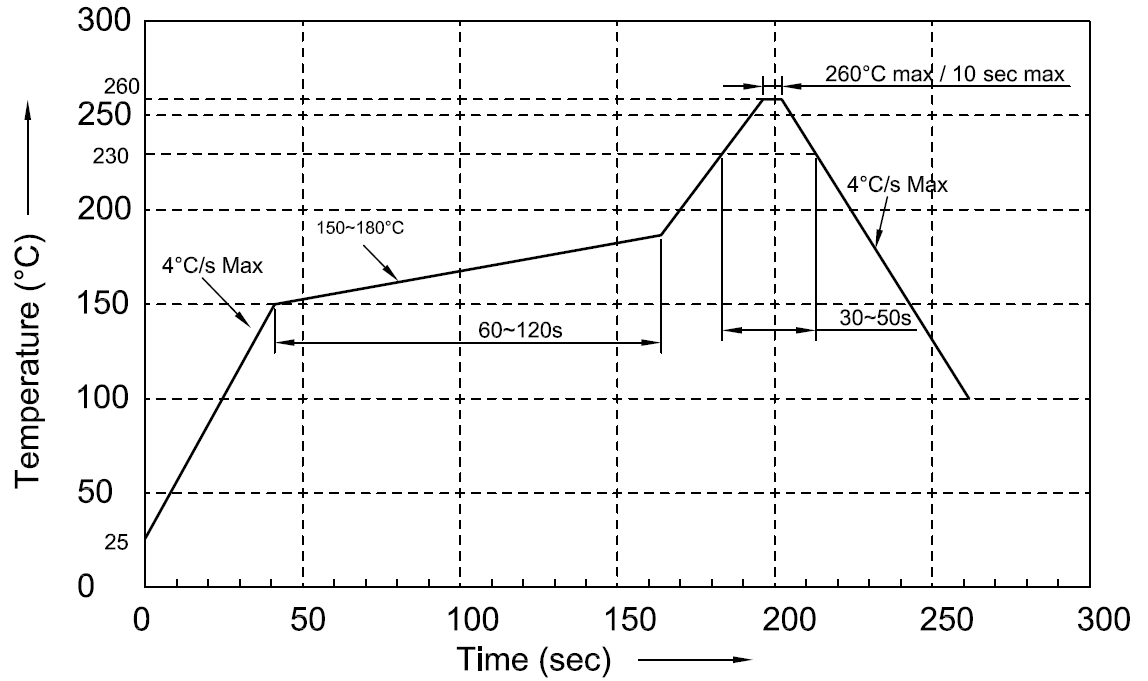

·SMT Reflow Soldering Instructions

Notes:

1. We recommend the reflow temperature 245±5℃.The maximum soldering temperature should be limited to 260℃ for 10s (max).

2. Don’t cause stress to the epoxy resin while it is exposed to high temperature.

3. Number of reflow process shall be 2 times or less.

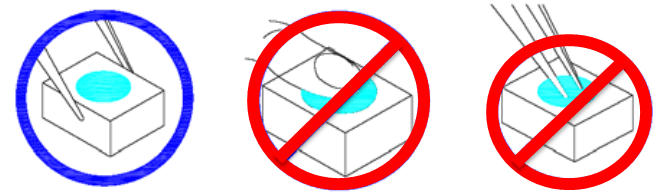

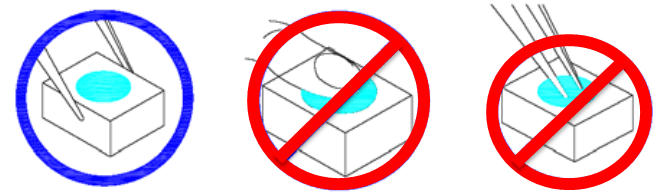

·Handling Precautions

Epoxy resin is hard & brittle and silicone is softer & flexible. Although its characteristic significantly thermal stress, it is more susceptible to damage by external mechanical force.

As a result, special handling precautions need to be observed during assembly using silicone encapsulated

LED products. Failure to comply might lead to damage and premature failure of the LED.

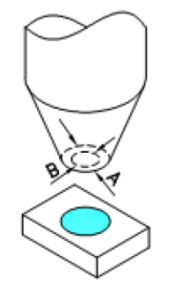

1.  Handle the component along the side surface by using forceps or appropriate tools (fig.1); do not directly touch or Handle the silicone lens surface, it may damage the internal circuitry(fig.2&3).

Handle the component along the side surface by using forceps or appropriate tools (fig.1); do not directly touch or Handle the silicone lens surface, it may damage the internal circuitry(fig.2&3).

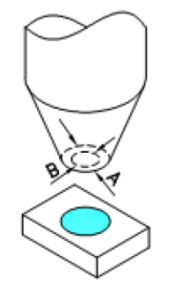

2. The outer diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air leaks. The inner diameter of the nozzle should be as large as possible. A pliable material is suggested for the nozzle tip to avoid scratching or damaging the LED surface during pickup.

The dimensions of the component must be accurately programmed in the pick-and-place machine to insure precise pickup and avoid damage during production.

3. Prevent stack together assembled PCBs containing.

PH<7. LEDs. Impact may scratch the silicone lens or damage the internal circuitry(fig.4).

4. 4. Non-suitable to operate in acidic environment, (Fig.5)

5. LED operating environment and sulfur element composition cannot be over 100PPM in the LED mating usage material.

·ESD (Electrostatic Discharge)

Static Electricity or power surge will damage the LED. Use of a conductive wrist band or anti-electrostatic glove is recommended when handing these LED. All devices, equipment and machinery must be properly grounded.

·Storage

In order to prevent the absorption of moisture, it is recommended to solder LITEKEY LEDs as soon as possible after unpacking the sealed envelope.

If the envelope is still packed, to store it in the environment as following:

1. Temperature:5℃-30℃(41℉-86℉) Humidity: RH 60% Max.

2. After this bag is opened, devices that will be applied to infrared reflow, vapor-phase reflow, or equivalent soldering process must be:

A. Completed within 168 hours.

B. Stored at less than 30% RH.

3. Devices required baking before mounting, if:(2)a or (2)b is not met.

4. If baking is required, devices must be baked under below condition:48 hour at 60℃±3℃.

·Other

1. Above specification may be changed without notice. LITEKEY will reserve authority on material change for above specification.

2. When using this product, please abserve the absolute maximum ratings and the instructions for using outlined in these specification sheets. LITEKEY assumes no responsibility for any damage resulting from use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets.

3. These specification sheets include materials protected under copyright of LITEKEY COMPANY LIMITED. Please don’t reproduce cause by anyone to reproduce them without LITEKEY’s consent.

·SMT Reflow Soldering Instructions

Notes:

1. We recommend the reflow temperature 245±5℃.The maximum soldering temperature should be limited to 260℃ for 10s (max).

2. Don’t cause stress to the epoxy resin while it is exposed to high temperature.

3. Number of reflow process shall be 2 times or less.

·Handling Precautions

Epoxy resin is hard & brittle and silicone is softer & flexible. Although its characteristic significantly thermal stress, it is more susceptible to damage by external mechanical force.

As a result, special handling precautions need to be observed during assembly using silicone encapsulated

LED products. Failure to comply might lead to damage and premature failure of the LED.

1.  Handle the component along the side surface by using forceps or appropriate tools (fig.1); do not directly touch or Handle the silicone lens surface, it may damage the internal circuitry(fig.2&3).

Handle the component along the side surface by using forceps or appropriate tools (fig.1); do not directly touch or Handle the silicone lens surface, it may damage the internal circuitry(fig.2&3).

2. The outer diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air leaks. The inner diameter of the nozzle should be as large as possible. A pliable material is suggested for the nozzle tip to avoid scratching or damaging the LED surface during pickup.

The dimensions of the component must be accurately programmed in the pick-and-place machine to insure precise pickup and avoid damage during production.

3. Prevent stack together assembled PCBs containing.

PH<7. LEDs. Impact may scratch the silicone lens or damage the internal circuitry(fig.4).

4. 4. Non-suitable to operate in acidic environment, (Fig.5)

5. LED operating environment and sulfur element composition cannot be over 100PPM in the LED mating usage material.

·ESD (Electrostatic Discharge)

Static Electricity or power surge will damage the LED. Use of a conductive wrist band or anti-electrostatic glove is recommended when handing these LED. All devices, equipment and machinery must be properly grounded.

·Storage

In order to prevent the absorption of moisture, it is recommended to solder LITEKEY LEDs as soon as possible after unpacking the sealed envelope.

If the envelope is still packed, to store it in the environment as following:

1. Temperature:5℃-30℃(41℉-86℉) Humidity: RH 60% Max.

2. After this bag is opened, devices that will be applied to infrared reflow, vapor-phase reflow, or equivalent soldering process must be:

A. Completed within 168 hours.

B. Stored at less than 30% RH.

3. Devices required baking before mounting, if:(2)a or (2)b is not met.

4. If baking is required, devices must be baked under below condition:48 hour at 60℃±3℃.

·Other

1. Above specification may be changed without notice. LITEKEY will reserve authority on material change for above specification.

2. When using this product, please abserve the absolute maximum ratings and the instructions for using outlined in these specification sheets. LITEKEY assumes no responsibility for any damage resulting from use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets.

3. These specification sheets include materials protected under copyright of LITEKEY COMPANY LIMITED. Please don’t reproduce cause by anyone to reproduce them without LITEKEY’s consent.